When it comes to power tools, the air reciprocating saw stands out as a versatile and efficient option for cutting through a variety of materials. Whether you’re a seasoned professional or a DIY enthusiast, selecting the right air reciprocating saw can make a significant difference in the quality and efficiency of your work. This article will guide you through the essential factors to consider when choosing an air reciprocating saw, ensuring you make an informed decision for your next project.

Understanding the Air Reciprocating Saw

An air reciprocating saw, often referred to as a pneumatic saw, is powered by compressed air rather than electricity or batteries. This tool is famed for its lightweight design and ease of use, making it ideal for tasks that require maneuverability and precision, such as cutting through metal, wood, and plastic. Unlike their electric counterparts, air reciprocating saws do not overheat, making them suitable for prolonged use in industrial settings.

Key Factors to Consider

When selecting an air reciprocating saw, several critical factors come into play:

- Power and Performance: Look for saws with a higher stroke per minute (SPM) rating for faster cutting speed. Typical SPM ranges from 2000 to 3000, and higher is generally better for efficiency.

- Stroke Length: The stroke length determines how deep the saw can cut in one motion. A longer stroke (usually between 3/4” to 1”) allows for deeper cuts, making it suitable for thicker materials.

- Weight and Handling: Lightweight models (typically weighing under 5 pounds) are easier to handle, especially during extended use. Consider the ergonomics of the tool, including grip comfort.

- Noise Level: Pneumatic tools can be loud. Check the decibel rating, as lower ratings will be more comfortable for prolonged use.

- Durability and Build Quality: Look for models made from heavy-duty materials, such as aluminum or high-strength plastics, to withstand tough job site conditions.

- Blade Compatibility: Ensure the saw is compatible with a variety of blades for different materials. Some saws accept universal blades, while others may require specific types.

- Brand Reputation: Choose reputable brands known for quality and customer support. Brands like Ingersoll Rand, Chicago Pneumatic, and DeWalt often receive high marks.

Types of Air Reciprocating Saws

Air reciprocating saws come in various configurations, each suited for different applications:

- Standard Reciprocating Saws: Ideal for general cutting tasks, these are versatile and can handle a range of materials.

- Compact Reciprocating Saws: Smaller and lighter, making them suitable for tight spaces and intricate cuts.

- Heavy-Duty Models: Designed for industrial use, capable of handling tougher materials and more demanding jobs.

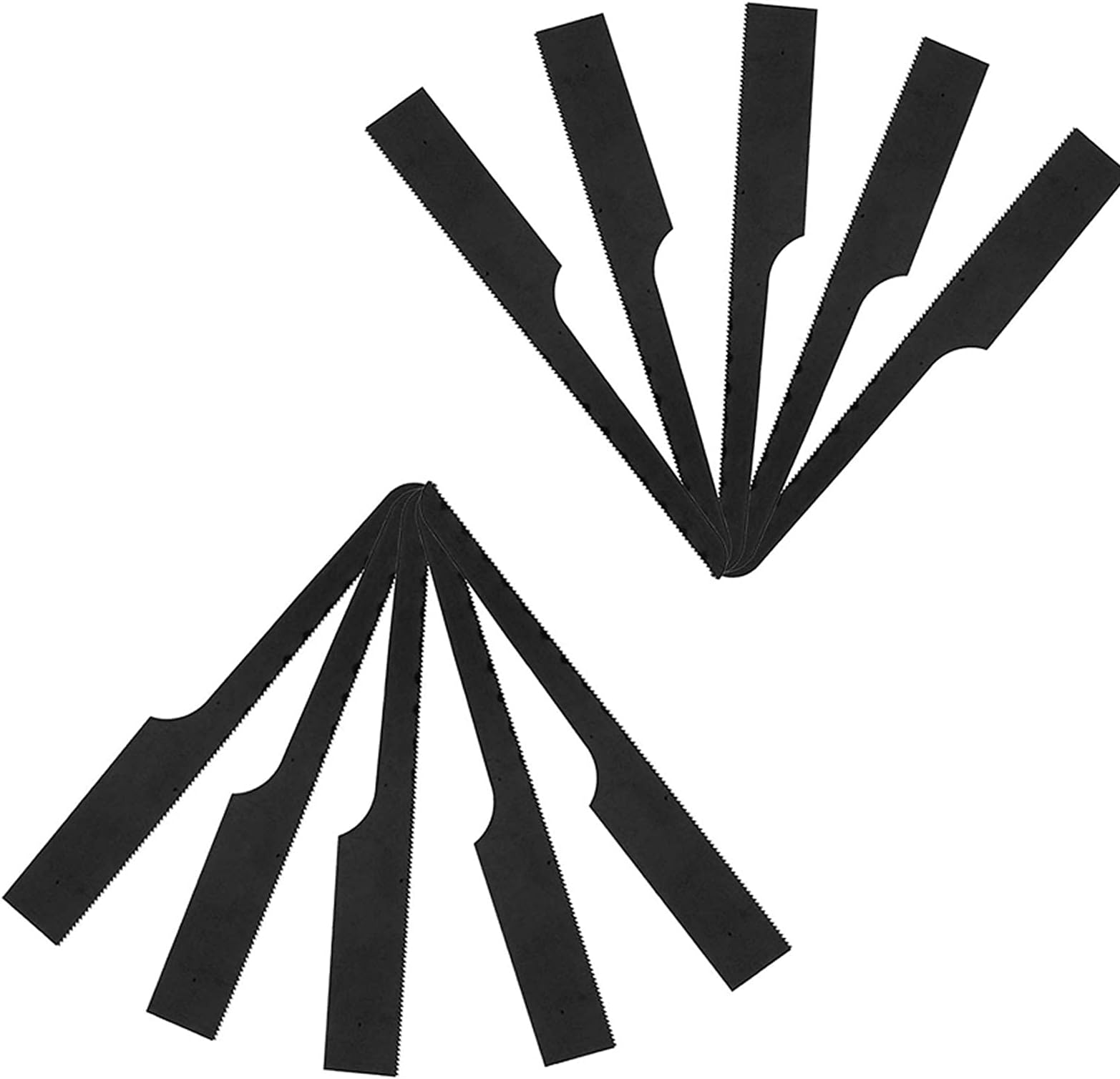

Choosing the Right Blade

The blade you select for your air reciprocating saw can significantly affect its performance. Here are some types of blades and their recommended applications:

- Wood Blades: Typically have fewer teeth per inch (TPI) for faster cuts.

- Metal Blades: Feature high TPI and are made from tougher materials like bi-metal or carbide to handle harder substances.

- Plastic Blades: Designed specifically for cutting plastic with a TPI that balances speed and finish.

Additionally, consider the type of shank your saw requires. Many air reciprocating saws use a universal shank design, allowing for easy blade replacement and compatibility with various brands.

Real-World Applications and Case Studies

Understanding how air reciprocating saws perform in real-world scenarios can help guide your decision. For instance, in a recent construction project, a contractor used an air reciprocating saw for cutting metal framing. He noted that the tool’s lightweight design allowed for extended use without fatigue, and the high SPM facilitated quick cuts, reducing the overall project timeline by 20%.

In another case, a DIY enthusiast used a compact air reciprocating saw for home renovations. She found that the tool’s maneuverability made it easier to navigate tight spaces, enabling her to complete intricate woodwork without damaging surrounding materials.

Maintenance Tips for Longevity

To ensure your air reciprocating saw lasts for years, regular maintenance is essential:

- Lubrication: Routinely lubricate the tool to keep internal components functioning smoothly.

- Air Supply Maintenance: Ensure clean, dry air is supplied to the tool to prevent internal corrosion and wear.

- Blade Inspection: Regularly check blades for wear and replace them as needed to maintain cutting efficiency.

- Storage: Store the tool in a dry, protected area to prevent damage from the elements.

Choosing the right air reciprocating saw involves understanding your specific needs and the capabilities of the tool. By considering factors such as power, weight, blade compatibility, and real-world applications, you can make an informed choice that will enhance your project outcomes. Remember to maintain your tool properly to ensure longevity and optimal performance. With the right air reciprocating saw in hand, you’ll be well-equipped to tackle any cutting task with confidence and precision.

Whether you’re cutting through metal in a professional setting or engaging in DIY home improvements, investing time in selecting the right tool pays off in efficiency and effectiveness. Happy cutting!